Types of Enclosures - Pumps and Caps for Cosmetic and Beauty Business

Overview of Enclosures in the Cosmetic and Beauty Industry

Packaging plays a crucial role in the cosmetic and beauty industry. It not only protects the product but also enhances its aesthetic appeal, making it more attractive to consumers. The right packaging ensures the product’s longevity, maintains its quality, and provides an extraordinary user experience, which can significantly impact customer satisfaction and product functionality.

Purpose of the Article

This article serves as a comprehensive guide to various types of pumps and caps used in the cosmetic and beauty industry. It aims to educate businesses on the benefits of selecting the appropriate enclosures for their products, thereby improving product performance, user experience, and overall brand image.

Airless Pumps

Definition and Functionality: Airless pumps are designed to dispense products without allowing air to enter the container, which helps in maintaining the product’s integrity. They work through a non-pressurized vacuum system. These pumps require a compatible container to latch onto.

Benefits for Preserving Product Integrity: Airless pumps prevent oxidation and contamination, extending the shelf life of the product. They are particularly beneficial for preservative-free and sensitive formulations.

Common Products Using Airless Pumps: Skincare products like serums, creams, and lotions often use airless pumps to protect their active ingredients.

Lotion Pumps

How Lotion Pumps Work: Lotion pumps are designed to dispense thicker, more viscous liquids. They operate by creating a vacuum that draws the product up through a dip tube. These pumps have high compatibility with various types of packaging.

Advantages for Viscous Products: Lotion pumps allow for controlled, mess-free dispensing of thick products, ensuring that the right amount is used each time. Large quantity of material can be dispensed through lotion pump

Popular Uses in the Industry: Commonly used for body lotions, hair conditioners, sunscreen, and any other product that has a thick formulation or requires large dispensing quantity in a single press.

Foaming Pumps

Mechanism Behind Foaming Pumps: Foaming pumps mix the liquid product with air to create foam upon dispensing. This is achieved through a special mechanism in the pump head. Compatible with specific containers designer for foaming pump

Ideal Products for Foaming Pumps: Products like facial cleansers, hand soaps, and mousse formulations benefit from foaming pumps due to their lightweight, airy application.

Environmental Benefits: Foaming pumps can reduce the amount of product used per application, promoting sustainability by minimizing waste.

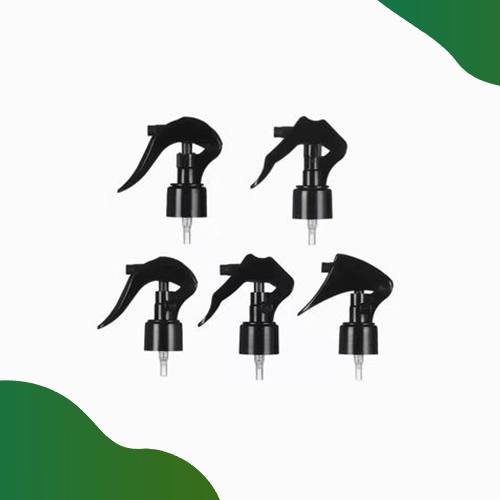

Trigger Sprayers

Description and Uses: Trigger sprayers are handheld devices that spray liquid when the trigger is pressed. They are typically used for larger volume applications. These pumps have high compatibility with various types of packaging.

Benefits for Larger Product Applications: Ideal for products that need to be evenly distributed over a wide area, such as hair sprays, body mists, and cleaning solutions.

Examples in Beauty Products: Used for products like leave-in conditioners, hair detanglers, and setting sprays.

Fine Mist Sprayers

How Fine Mist Sprayers Operate: Fine mist sprayers disperse liquid into a fine mist, providing light and even application.

Ideal Cosmetic Applications: Perfect for facial mists, makeup setting sprays, and fragrance products.

Consumer Advantages: Provides a refreshing, even coverage without soaking the skin or hair, enhancing the user experience.

Treatment Pumps

Specific Uses for Treatment Pumps: Treatment pumps are designed for precise, targeted application of concentrated products.

Common Types of Treatments Using These Pumps: Frequently used for eye creams, acne treatments, and spot serums.

Benefits for Targeted Application: Allows users to apply the exact amount needed to specific areas, maximizing product efficiency and effectiveness.

Serum Pumps

Definition and Functionality: Serum pumps are designed to dispense small, controlled amounts of highly concentrated products.

Advantages for Concentrated Products: Ensures precise dosage, minimizing waste and enhancing the efficacy of the product.

Common Uses in Cosmetics: Typically used for facial serums, anti-aging treatments, and vitamin C serums.

Types of Caps for Cosmetics

Screw Caps

Definition and Variations: Screw caps are closures that are screwed onto the container’s neck. They come in various designs, including child-resistant and tamper-evident options.

Advantages for Product Security: Provide a tight seal, preventing leaks and contamination, and are easy to open and close.

Popular Uses in Cosmetics: Commonly used for creams, lotions, and liquid foundations. Suitable for formulation which can flow easily.

Flip-Top Caps

How Flip-Top Caps Function: Flip-top caps have a hinged lid that can be flipped open and closed with one hand.

Benefits for User Convenience: Easy to use, allowing quick access to the product while preventing spills and leaks.

Examples in Beauty Products: Often used for shampoos, conditioners, and body washes.

Disc Top Caps

Mechanism and Uses: Disc top caps have a disc that is pressed down on one side to open and dispenses the product through a small hole.

Advantages for Controlled Dispensing: Provides controlled dispensing, which is ideal for liquid products where precise amounts are needed.

Common Applications: Frequently used for facial cleansers, liquid soaps, and toners.

Snap-On Caps

Description and Mechanism: Snap-on caps are designed to snap onto the container’s neck, creating a secure seal.

Benefits for Product Safety: Easy to apply and remove, offering a secure closure that protects the product. Removal of the snap-on cap is difficult, it is designed to keep the product secure

Use Cases in Cosmetics: Commonly used for creams, gels, and lotions.

Dropper Caps

Description and Uses: Dropper caps include a pipette that allows precise dispensing of liquid products.

Benefits for Precise Dispensing: Ideal for products that require controlled dosage, such as serums and essential oils.

Ideal Products for Dropper Caps: Used for facial oils, serums, and liquid supplements.

Material Considerations

Plastic Enclosures

Types of Plastic Used: Common plastics include PET, HDPE, and PP, each with its own benefits and uses.

Benefits and Drawbacks: Lightweight, durable, and cost-effective, but can raise environmental concerns if not properly recycled.

Environmental Considerations: Importance of choosing recyclable or biodegradable plastics to reduce environmental impact.

Glass Enclosures

Advantages for Product Preservation: Non-reactive and impermeable, preserving the product’s purity and extending shelf life.

Drawbacks and Considerations: Heavier and more fragile than plastic, increasing shipping costs and risk of breakage.

Common Uses in Luxury Cosmetics: Often used for high-end perfumes, serums, and essential oils due to their premium feel and look.

Metal Enclosures

Benefits for Product Protection: Highly durable and offers excellent protection against light and air, preserving product quality.

Drawbacks and Common Concerns: Can be more expensive and heavier, affecting transportation and handling.

Examples in High-End Packaging: Used for luxury creams, balms, and certain makeup products due to their elegant appearance.

Customization and Branding

Importance of Customization

Impact on Brand Identity: Custom packaging can reinforce brand identity and make products stand out on the shelves. There are various options brands can opt for when customizing enclosures, such as customized metal collars, customized color of the enclosure, and customized Metallic UV coating on the enclosure. Additional customization such as debossing or embossing on the enclosure by making a customized moulid or encasing it in a tertiary sleeve.

Trends in Cosmetic Packaging

Current Trends and Innovations: Sustainable packaging, minimalistic designs, and multifunctional packaging are trending in the industry.

Predictions for Future Packaging Trends: Anticipated trends include smart packaging, refillable containers, and increased use of biodegradable materials.

Conclusion

Summary of Key Points

- Various types of pumps and caps serve different functions and benefits in cosmetic packaging.

- Choosing the right enclosure enhances product performance, user experience, and brand image.

Final Thoughts

Emphasize the importance of prioritizing packaging in product development to improve customer satisfaction and brand success. Encourage readers to explore innovative and sustainable packaging options to stay ahead in the competitive beauty industry.

Frequently Asked Questions (FAQs)

Airless pumps protect the product from air exposure, preventing oxidation and contamination, which is crucial for maintaining the efficacy of sensitive skincare formulations.

Foaming pumps dispense product in a foam form, which can reduce the amount of product used per application, leading to less waste and longer product life.

Considerations include the product’s viscosity, user convenience, product safety, brand aesthetics, and environmental impact.

Child-resistant packaging prevents accidental ingestion of potentially harmful products by making them difficult for children to open, enhancing safety.

Plastic can contribute to pollution if not recycled, while glass and metal are more sustainable but heavier and more costly to transport. Choosing recyclable or biodegradable materials is crucial for reducing environmental impact.

Attractive and functional packaging can enhance the perceived value of a product, create a memorable unboxing experience, and build brand loyalty.

Current trends include eco-friendly materials, personalized packaging, interactive and smart packaging, and designs that reflect minimalism and luxury.